AG/CAD delivers savings to DST

- steve8125

- Jan 25, 2016

- 2 min read

Print Solutions

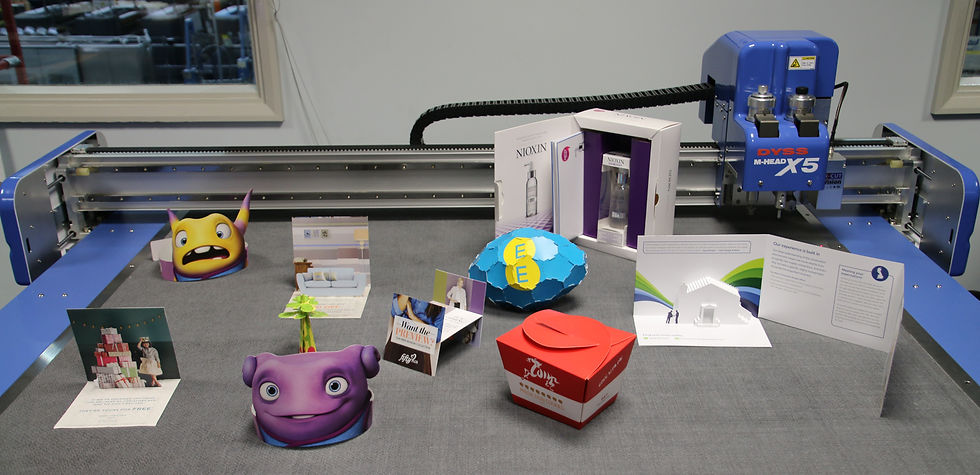

DST has recently installed a DYSS X5-1310T sample making/digital cutter from AG/CAD.

The company produces over one billion statement images each year; it is responsible for 836 million posted mail packs that sees every UK household receive a DST printed mail every 13 days. Furthermore, the company picks and packs over 828,000 items each month, and its customer base reads like a 'who's who' of the retail, banking and service sectors. Dealing with such staggering quantities, it’ is no surprise the company's busy design department at the Nottingham facility needed to upgrade its ageing sample cutting machine to a DYSS X5 digital cutter.

Discussing the justification of buying a new cutting machine, product development manager Steve Hutchinson said: ‘Like any large company, we needed to investigate and justify our choice of supplier and machine. With a design department that creates over 10,000 design samples every year, reliability was a critical factor. The new cutting table would replace an old Studio Sampler cutting machine that AG/CAD supplied in 1999. As we had been using AG/CAD's Kasemake CAD package in conjunction with the machine for over 15 years, we were confident of the outstanding products and technical support. This proven support mechanism and equipment reliability was a key factor in our purchasing decision.’

DST Nottingham’s site has a busy shop floor with printing presses generating average print runs from 25,000 to five million. It was identified that by producing varnish blankets for its sheetfed presses on a precise cutting machine, set up time and cost savings could be made further downstream. Since purchasing the DYSS X5-1310T digital cutting table, the company has quantified the savings. Steve continued, ‘By producing varnish blankets on the DYSS X5 in just a few minutes, we are saving press time of approximately 30 minutes on simple jobs, more on complex ones. Over the duration of a calendar year, this is saving us £1000s in make ready down time. This was a major factor in the investment in the DYSS X5.’

The original machine that was replaced by the DYSS was continually cutting from 70 to 350 g/m2 paper as well as folding boxboard. However, with a diverse product range, DST needed a more precise, flexible and also robust solution for making leaflets, booklets and mailers from 70 to 350 g/m2, and packaging from folding boxboard up to 750 micron range. ‘The X5 comfortably processes everything we do. Furthermore, the K-Cut Digital Camera Vision System ensures we have more precise cutting, as it identifies the registration marks on printed jobs to give us impeccable accuracy levels. This allows us to precisely check duplex print back ups for the production department, saving time and increasing accuracy. We also convert die cut proofs for production jobs, due to the high precision of the machine,’ added Steve.

‘From a productivity standpoint, the X5 is considerably faster than its predecessor. This has reduced bottlenecks and improved throughput for our busy design department.’

Comments